Hot Work in Cargo Hold

By Capt. Huy / V-Isea Vietnam Co., Ltd - Steer Your Dream

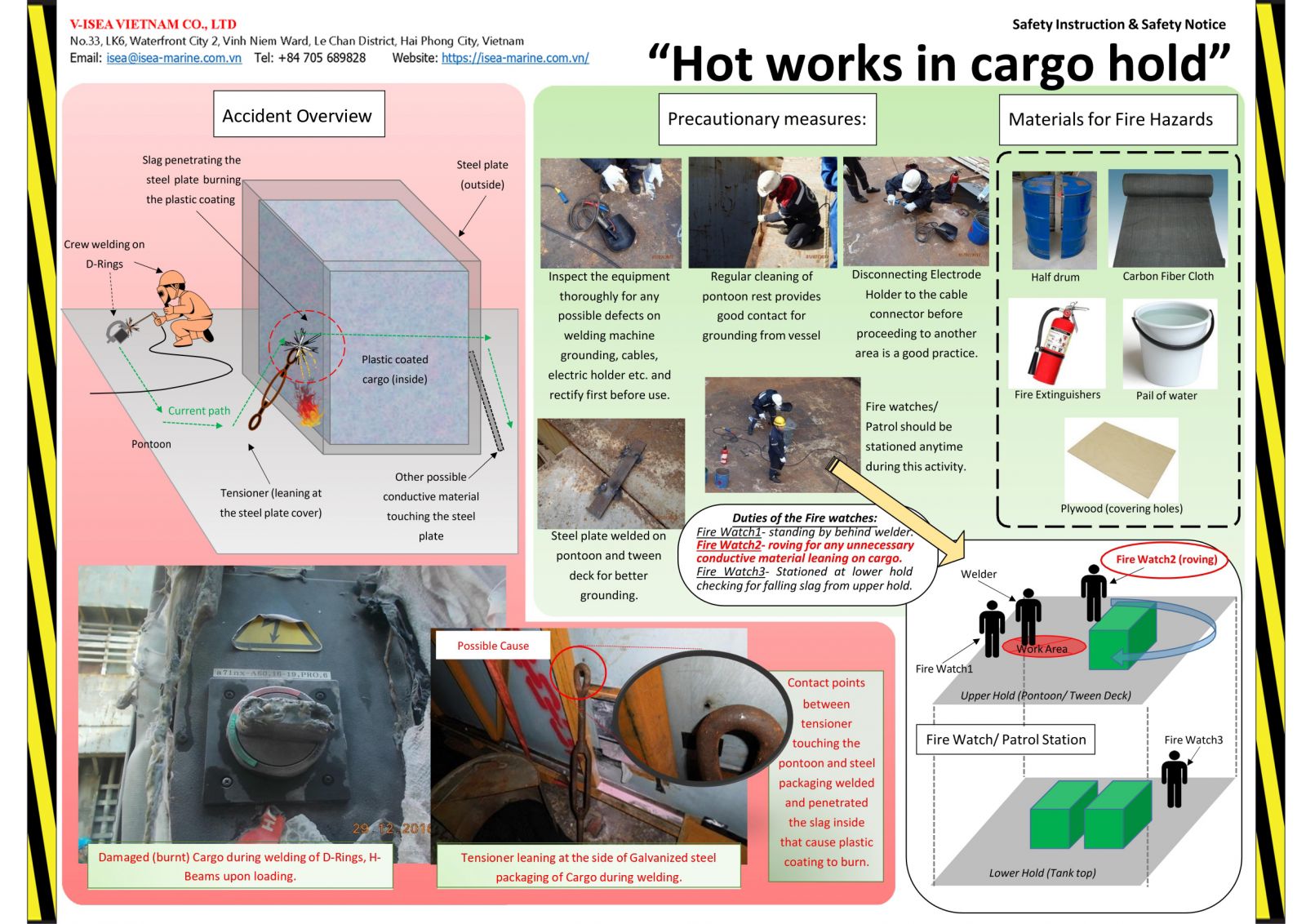

Hot work in cargo hold increased potential risk of fire and damage cargo if without care and not strictly follow hot work in cargo hold procedure.

Hot work traditionally includes, but is not limited to, any work requiring the use of electric arc or gas welding equipment, cutting burner equipment or other forms of naked flame, as well as heating or spark generating tools which are not certified for use in hazardous areas.

Hot Work procedures

1.Hot work procedures must be developed based on MSC/Circ.1084, Principles for Hot Work on Board All Types of Ships. The procedures must be incorporated into the SMS of the ship where such systems are required.

2. The procedures must ensure that:

- any hot work is justified and deemed necessary for the safety and/or the immediate operation of the ship and that all viable alternatives have been considered;

- the hot work policy supports a permit-to-work system that is easily understandable to the crew;

- a risk assessment has been conducted to consider all hazards, including but not limited to:

-entering enclosed spaces if applicable to the job

-the type of cargo being carried;

-surrounding hazards near the work area (e.g. ventilator heads);

-whether a fitting can be removed from a hazardous cargo area before hot work is performed;

-availability of local fire-fighting equipment;

-the anticipated duration of the work; and

-the appointment of a suitably qualified responsible officer-in-charge.

- the Master maintains overriding authority and discretion to take actions deemed necessary in accordance with MI-108, §7.41.1.

3. Industry guidance appropriate to the ship type is to be utilized when developing the hot work procedures. This guidance includes, but is not limited to, the most recent versions of:

- OCIMF, Guidelines on Safety Management Systems for Hot Work and Entry into Enclosed Spaces;

- ISGOTT, International Safety Guide for Oil Tankers and Terminals (ISGOTT), Chapter 9, Management of Safety and Emergencies, and Chapter 10, Enclosed Spaces;

- ICS, Tanker Safety Guide (Chemicals);

- ICS, Tanker Safety Guide (Liquefied Gas);

- BLU Code, The Draft Code of Practice for the Safe Loading and Unloading of Bulk Carriers; and

- ILO publication, Accident prevention on board ship at sea and in port.

Hot work within the cargo area is prohibited on ships that are carrying or have carried a flammable substance or those that emit flammable vapors, except when the process is strictly controlled in accordance with the ship’s hot work procedures.

As such, the Isea Marine superintendent recommends the following precautions to be taken on board:

- Ensure the space is well ventilated

- If flammable gasses are suspected then test before and during the hot work task

- Check that the immediate area is free from combustibles

- Check neighboring or connected areas (such as another side of bulkhead) or internal areas (such as inside a tank) that may be heat affected to make sure they are free from flammables and combustibles

- Bulkhead insulation may need to be removed

- If appropriate, use portable barriers or shields and warning signs

- Maintain a dedicated fire watch for both the immediate area and any potentially affected neighbouring/ connected areas throughout the full operation

- Proper use of Personal Protective Equipment, such as welding mask/ goggles, gloves, apron

- Make sure that the welding and burning equipment is properly maintained and serviced

- Welding and burning equipment must be checked by a competent person before every use. Check that the hoses, cables and connections are in good condition

- Check that flame arrestors are in place on both the oxygen and acetylene lines at both the torch and bottle ends

- Persons carrying out the hot work should be properly trained and checks made to ensure they are competent.